Moringa Agriculture-Based Clusters (ABCs)

Please Take note: This project is now part of the Botwana Economic Tranformation Program (BETP): https://betp.gov.bw/#agriculture-investment-opportunities

ABCs A Transformational Framework for Community-Centric, Climate-Smart, and Commercial Agriculture in Botswana and Africa

1. Introduction

Moringa Agriculture-Based Clusters (ABCs) constitute a national, strategic, and highly structured agricultural development architecture designed to reshape both rural and urban economies through unified production systems, standardized processing platforms, and integrated market access pathways. This model elevates agriculture from fragmented, small-scale activity into a coordinated, industrial, and export-driven economic sector. By bringing farmers, processors, development partners, and market institutions into one cohesive system, the ABCs create an environment where agricultural productivity directly translates into industrial growth, job creation, and sustainable national development. Read more about ABCs : https://www.farmersprideinternational.org/agri-based-clusters

At the centre of this model is Moringa Oleifera, positioned as Botswana’s anchor crop—a crop capable of stabilizing farmer incomes, stimulating rural industrialization, and enabling the emergence of multiple value chains across food, nutraceuticals, cosmetics, pharmaceuticals, animal feed, and climate-smart technologies. Moringa’s resilience to drought, rapid growth rate, regenerative qualities, and its exceptionally high commercial value make it an ideal foundation upon which to build large-scale agricultural transformation. As an anchor crop, it not only generates immediate income for farmers but also provides the financial base required for farmers to diversify into sorghum, millet, sunflower, soya beans, horticulture, and other high-value agricultural ventures.

![Moringa Products Market Size, Share & Global Report [2028]](https://fbi-reports-file.s3.us-west-2.amazonaws.com/fbi_l/img/featured_images/moringa_products_market.webp)

The ABC framework forms a core component of the Rural and Urban Agriculture Innovative Production Programme (RUAIPP)—a national programme established to integrate innovation, climate resilience, and agro-industrial systems into Botswana’s agricultural transformation agenda. RUAIPP promotes a unified, scalable, and technologically enabled agriculture sector, ensuring that communities across Botswana can participate meaningfully in production, processing, and export opportunities while contributing to national food security and sustainable livelihoods. Read more about RUAIPP: Read more about the RUAIPP: https://www.farmersprideinternational.org/fpi-i-ruaipp-agriculture-program

The implementation of Moringa ABCs is collaboratively driven by an Agriculture Based Cluster led by Hunter' Global Network Pty Ltd and Botswana’s leading agro-development institutions: Farmer’s Pride International (FPI), providing technical oversight, certification pathways, export systems, and production standards; Uphopia Farms Pty Ltd, serving as the national hub for training, seedling production, and field capacity development; Shammah Global Group Pty Ltd, leading processing, packaging, branding, and value addition; Legacy Media Pty Ltd, spearheading communication, investor relations, and public awareness campaigns; Girl Child Movement (GCM), championing youth and women empowerment, leadership development, and inclusive participation; and Agri-Link, strengthening farmer mobilisation, cooperative systems, and supply chain integration. Together, these institutions operate as a unified ecosystem, each fulfilling a strategic role within the ABC architecture.

A mordern Moringa Farm :

Through this multi-stakeholder approach, Moringa ABCs emerge as a national instrument for job creation, industrialization, export diversification, climate resilience, and community development. The model directly contributes to Botswana’s Botwana Economic Tranformation Program (BETP): https://betp.gov.bw/#agriculture-investment-opportunities, the Sustainable Development Goals (SDGs), and the country’s broader economic transformation agenda. It lays the foundation for an inclusive, competitive, and future-ready agricultural economy capable of generating thousands of jobs, empowering women and youth, revitalizing rural communities, and positioning Botswana as a continental leader in Moringa production, processing, and global exports.

2. Defining Moringa Agriculture-Based Clusters

A Moringa ABC is a coordinated geographic concentration of farmers, processors, service providers, and support institutions working together to grow, process, and commercialize Moringa at scale.

Rather than operating in isolation, individual farmers become part of a coordinated agricultural network designed to achieve scale, consistency, efficiency, and competitiveness. The cluster model enables Moringa production to move beyond small, fragmented farming towards an organised industrial system capable of supplying national, regional, and international markets sustainably and reliably.

A Moringa ABC is not defined by a single plot of land; it is defined by the collective capacity of multiple farms operating under shared production standards, governed policies, and centralised processing facilities. The structure includes anchor farms, satellite farms, youth and women groups, micro-growers, community production blocks, nurseries, processing hubs, logistics networks, training institutions, and market linkages — all interconnected through a governance framework that ensures accountability, quality, traceability, and coordinated supply.

Countries Growing Moringa.

At the heart of this cluster model is a centralised processing and value-addition hub, which serves as the engine of the entire ecosystem. Here, raw Moringa leaves, seeds, pods, roots, and biomass from all participating farms are transformed into an array of high-value products including powder, tea, capsules, seed oil, cosmetics, animal feed, cereals, and industrial extracts. This hub eliminates post-harvest losses, standardises quality, ensures compliance with export regulations, and raises the commercial value of every kilogram produced at the farm level.

Accompanying the processing hub is a structured governance system that includes cluster committees, farmer registries, quality assurance teams, export support offices, technical working groups, and financial inclusion mechanisms. This system ensures coordination, equitable participation, transparent reporting, and collective decision-making.

In operational terms, a Moringa ABC unites farmers, youth, women, processors, exporters, financiers, and buyers into one coordinated ecosystem that generates wealth collectively rather than individually. By sharing resources such as machinery, training, certification, processing facilities, and market access, cluster members benefit from economies of scale that would otherwise be unattainable for single, isolated farmers. This collective power reduces production costs, increases profit margins, and strengthens bargaining positions in local and global markets.

In this way, the ABC becomes more than a production model — it becomes a community development mechanism, a business network, and an industrial growth platform capable of transforming local economies and establishing Moringa as a national anchor crop across Botswana and the wider region.

3. The Core Components of a Moringa ABC

Each cluster contains the following pillars:

3.1 Production Pillar

- Farmers growing Moringa on standardized densities (up to 70,000 trees per hectare).

- Cluster nurseries supplying seedlings.

- Training centres (Uphopia Farms) ensuring technical compliance.

- EcoCert-aligned production systems.

3. The Core Components of a Moringa Agriculture-Based Cluster (ABC)

A fully functional Moringa Agriculture-Based Cluster is built upon several interdependent pillars that collectively ensure high productivity, consistent quality, economic viability, and long-term sustainability. These pillars create the structural backbone of the ABC model, ensuring that farmers, processors, institutions, and markets operate seamlessly within a unified value chain. The first and most critical of these is the Production Pillar, which establishes the agricultural foundation upon which all subsequent value-adding activities depend.

3.1 Expanded Production Pillar

The Production Pillar focuses on establishing a large-scale, standardised, and climate-smart Moringa farming system across all participating farms. It is designed to ensure uniformity in production methods, consistency in output quality, and reliability in supply volumes required for national and international markets. This pillar transforms scattered producers into a harmonised production force, united under a common set of standards and supported by integrated technical, agronomic, and institutional systems.

3.2 Standardised High-Density Moringa Production (Up to 70,000 Trees per Hectare)

A defining feature of the ABC model is the adoption of

high-density Moringa cultivation, reaching up to 70,000 trees per hectare. This

density is scientifically proven to maximise biomass output, leaf production,

and seed yield while ensuring optimal land-use efficiency. It enables farmers

to achieve consistent yields capable of supporting industrial-level processing

and fulfilling long-term supply contracts for both domestic processors and

export buyers.

Standardisation ensures that every cluster adheres to the same spacing,

pruning, irrigation, fertilisation, and harvest protocols so that production

remains predictable, uniform, and traceable.

3.3 Cluster-Based Seedling Nurseries

Ensure reliable and continuous access to high-quality

planting materials, each ABC maintains a dedicated nursery system. These

cluster nurseries are responsible for producing disease-free, climate-adapted,

and genetically superior seedlings, enabling farmers to establish plantations

efficiently and consistently across all participating farms.

Nurseries also play a strategic role in replacing dead plants, expanding

production blocks, and supporting new farmers entering the cluster. This

guarantees year-round supply of planting material, reducing delays and

enhancing the scalability of the ABC model.

3.4 Training Centres Led by Uphopia Farms

Training is a foundational requirement for ensuring that farmers meet the agronomic, environmental, and certification standards demanded by premium markets. Uphopia Farms serves as the official technical and training arm of the ABC ecosystem, providing structured capacity-building programmes that include:

- Moringa agronomy

- Soil and water management

- EcoCert-compliant farming practices

- Harvesting and post-harvest handling

- Pest and disease management

- Climate-smart agriculture techniques

- Farm record-keeping and digital reporting

Through these training centres, farmers receive continuous support, technical supervision, and monitoring to ensure that all production aligns with RUAIPP standards and global best practices.

4. EcoCert-Aligned Production Systems

Export markets—especially the EU, USA, Middle East, and

Asia—require strict compliance with organic and ethical production standards.

To meet these requirements, the Production Pillar incorporates full alignment

with EcoCert, HACCP, and global organic certification frameworks.

This includes:

- Use of organic fertilisers and bio-stimulants

- Avoidance of synthetic chemicals

- Traceable farm operations

- Soil and water conservation strategies

- Environmental protection protocols

- Worker safety, gender inclusion, and labour compliance

- Audit-ready documentation and batch tracking

EcoCert compliance not only ensures access to premium export markets but also enhances trust, transparency, and global competitiveness of Botswana’s Moringa products.

Summary

The Production Pillar of a Moringa ABC is the engine that powers the entire cluster ecosystem. Through standardised planting densities, efficient seedling systems, robust farmer training, and adherence to global certification standards, the ABC model guarantees high-quality production at scale. This creates the foundation upon which processing, value addition, export, and community wealth-building are built.

5. Processing & Value Addition

Cluster members will supply raw materials such as (leaves, seeds, pods, roots) to the cluster processing hub which manufactures the following products:

- Moringa powder

- Moringa tea

- Moringa oil

- Moringa capsules

- Moringa cosmetics

- Moringa animal feed

- Moringa water purification products

- Moringa honey

- Moringa-infused cereals (with sorghum & millet)

- Many more products across 17 structured value chains

The processing pillar transforms farmers from producers into manufacturers, multiplying income and export earnings.

5.1 Marketing & Export Pillar

FPI will leads the exports through Hunter’s Global Network and coordinates:

- Export permits

- Certification (EcoCert, HACCP, organic compliance)

- International buyer linkages

- Trade negotiations under AfCFTA & SADC

- Branding and packaging through Shammah Global Group

Clusters become supply nodes for national and international markets.

5.2 Governance Pillar

Each Agriculture-Based Cluster is led by Hunter’s Global Network and has:

- A Steering Committee

- Management

- Farmer Registry

- Constitutions & by-laws

- Traceability systems

- Digital reporting mechanisms for production, climate, soil & harvest data

- Compliance teams for quality control, environmental standards, and water management

This strengthens accountability, performance, and transparency.

5.3 Finance & Investment Pillar

Through HGN, clusters access:

- Financing opportunities

- Insurance products

- Capital equipment loans

- Grants and development funding

- Carbon credit trading platforms

This transforms clusters into investment-ready agricultural enterprises.

6. Why Moringa is the Anchor Crop

Moringa is chosen because it offers the following:

6.1 Exceptionally High Returns

Under Botswana conditions:

- Worst-case: 0.3 kg × 6 harvests = 800,000 BWP per hectare/year

- Base-case: 0.5 kg × 6 harvests = 1.4 million BWP per hectare/year

- Best-case: 0.5 kg × 8 harvests = 1.6 million BWP per hectare/year

These numbers make Moringa among the most profitable crops globally.

6.2 Climate Change Mitigation

- High carbon sequestration

- Drought tolerance

- Soil restoration

- Water efficiency

- Supports national NDC and SDG targets

7. Industrial and Economic Impact

Community Unity and Economic Empowerment

Moringa Oleifera supports 17 industrial value chains,

each forming a strategic economic pillar for agro-processing, manufacturing,

export development, and national industrialization.

Every value chain below now begins with Production of… or Manufacturing

of…, as requested.

1. Production of Moringa Leaf Powder (Nutraceutical Grade)

This value chain focuses on the drying, milling, and

micronization of Moringa leaves into high-nutrient powder. Powder is used

globally in health foods, supplements, and pharmaceuticals.

Industrial Role: A core raw material for capsules, teas, foods, and

beverages.

Economic Impact: High export value with stable international demand.

2. Production of Moringa Herbal Tea (Flakes & Tea Bags)

Leaves are dried, crushed, and packed into tea bags or loose

herbal tea formats.

Industrial Role: Part of the herbal beverage, detox, and wellness

industries.

Economic Impact: High profit margins, fast-moving consumer product.

3. Manufacturing of Moringa Capsules (Nutraceutical Supplements)

Powder is encapsulated in GMP-compliant facilities for

pharmaceutical-grade supplements.

Industrial Role: Entry into health, pharmaceutical, and global

supplement markets.

Economic Impact: Premium-priced product with high export potential.

4. Production of Medicinal Extracts (Bioactive Compounds & Concentrates)

Moringa leaves, seeds, and roots are processed into

medicinal extracts, tinctures, and concentrates.

Industrial Role: Input for herbal medicines, therapeutic blends, and

modern pharmaceuticals.

Economic Impact: High-value global herbal medicine market.

5. Manufacturing of Moringa Cosmetics (Soaps, Lotions, Creams, Hair Products)

Cosmetic-grade Moringa powder and oil are used to produce

soaps, lotions, conditioners, and skincare creams.

Industrial Role: Entry into the billion-dollar beauty and skincare

industry.

Economic Impact: Creates SMEs and export-ready beauty products.

6. Production of Moringa Skincare Oils (Cold-Pressed Ben Oil)

Moringa seeds are cold-pressed to extract premium cosmetic

oil.

Industrial Role: Used in luxury skincare, massage oils, aromatherapy,

and beauty formulations.

Economic Impact: High-value product with strong demand in EU, USA, and

Asia.

7. Manufacturing of Moringa-Based Cereals (Sorghum-Millet-Moringa Blends)

Moringa powder is incorporated into sorghum, millet, maize,

or wheat-based cereals for fortified nutritional products.

Industrial Role: Supports school feeding programmes and health-food

industries.

Economic Impact: Expands agro-processing and local manufacturing.

8. Manufacturing of Moringa Animal Feed (Pellets & Meal)

Dried Moringa leaves are processed into pellets or meal for

livestock feed.

Industrial Role: Reduces dependence on imported feed ingredients.

Economic Impact: Cuts feed costs, boosts livestock productivity, and

creates new feed companies.

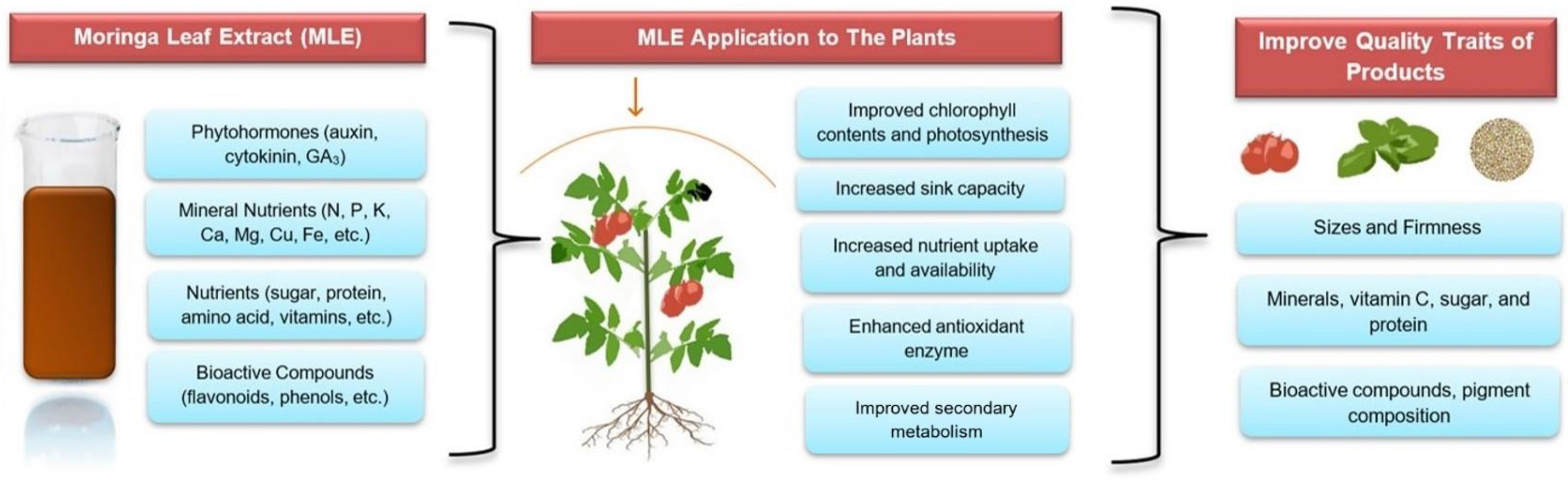

9. Production of Moringa Fertilizer (Organic Bio-Stimulators)

Leaves, seeds, and extracts are used to produce organic

fertilizers and plant hormone boosters rich in zeatin.

Industrial Role: Supports regenerative agriculture and organic farming

systems.

Economic Impact: Reduces chemical fertilizer imports and supports soil

health industries.

10. Manufacturing of Moringa Water Purification Products (Seed Coagulants)

Crushed Moringa seeds are processed into natural

water-purifying agents.

Industrial Role: Used in rural water systems, households, and municipal

treatment.

Economic Impact: Low-cost, eco-friendly purification alternative.

11. Production of Moringa Protein Supplements (Sports & Medical Nutrition)

Moringa powder is blended into protein shakes, powders, and

recovery supplements.

Industrial Role: Expands into sports nutrition, medical nutrition, and

wellness markets.

Economic Impact: High-value segment with global growth.

12. Manufacturing of Moringa Energy Bars (Functional Snacks)

Moringa is incorporated into snack bars, granola bars, and

fortified biscuits.

Industrial Role: Supports FMCG and functional food industries.

Economic Impact: Creates small industries and health-based brands.

13. Production of Moringa Bread and Confectionery (Bakery Applications)

Bakers integrate Moringa powder into bread, rolls, cakes,

muffins, and cookies.

Industrial Role: Mainstream food manufacturing enriched with superfood

nutrition.

Economic Impact: Opens new product lines in bakeries and confectionery

companies.

14. Manufacturing of Moringa Beverages (Juices, Concentrates, Smoothies)

Moringa powder or extracts are used to produce juice blends,

smoothies, and nutrient drinks.

Industrial Role: Part of functional beverages and wellness drinks.

Economic Impact: High export potential for ready-to-drink products.

15. Production of Moringa Cattle Feed (Protein-Rich Fodder)

Fresh or dried Moringa biomass is processed into

high-protein fodder for cattle.

Industrial Role: Supports dairies, feedlots, and cattle farms.

Economic Impact: Increases milk yields, reduces feed imports, and

enhances livestock growth.

16. Manufacturing of Moringa Poultry Feed (Broiler & Layer Concentrates)

Moringa meal is integrated into poultry feed formulations.

Industrial Role: Enhances egg production, improves immunity, and boosts

meat quality.

Economic Impact: Reduces mortality and feed costs for poultry farmers.

17. Production of Pharmaceutical-Grade Moringa Products (Medicinal Formulations)

Moringa extracts and compounds are transformed into

medicinal tablets, ointments, anti-inflammatory formulations, and diabetic

supplements.

Industrial Role: Positions Botswana in natural pharmaceutical

manufacturing.

Economic Impact: High revenue potential in global therapeutic markets.

18. Production of Export Commodities (Seeds, Leaf Flakes, Biomass, Crude Oil)

This includes semi-processed products such as cleaned seeds,

crude oil, dried leaf flakes, whole leaves, and raw biomass.

Industrial Role: Foundation for international trade under AfCFTA, SADC,

EU, GCC.

Economic Impact: Generates immediate foreign currency revenue.

Conclusion – A Fully Integrated Industrial Ecosystem

With these 17+ value chains levels, Moringa Oleifera becomes not a single crop, but a complete multi-sector industrial economy, capable of transforming:

- Rural development

- Youth and women empowerment

- Manufacturing

- Export diversification

- Climate resilience

- National GDP growth

This is why Moringa is the anchor crop for Botswana.

Clusters unite people—women, youth, men, farmers,

institutions—under one economic vision.

Members benefit collectively from:

- Shared machinery

- Shared knowledge

- Shared processing hubs

- Shared markets

This creates economies of scale and reduces production costs.

8. Social and Economic Impact of Moringa ABCs

Moringa ABCs create:

8.1 Employment

- 5,000 direct jobs by 2028

- 53,000+ direct and indirect jobs along the 17 value chains by 2033

- 153,000 direct and indirect jobs along the 17 value chains by 2036

- Massive youth and women participation across Botswana

8.2 Industrialization

In the long run Clusters will become mini-industries that produce the following:

- Food

- Medicine

- Cosmetics

- Animal feeds

- Carbon credits

- Export goods

8.3 Rural Development

Moringa Agriculture-Based Clusters (ABCs) are deliberately designed as rural economic transformation engines, turning villages, settlements, and remote localities into vibrant centres of agro-industrial activity. Instead of rural communities depending solely on subsistence farming or seasonal employment, the cluster model establishes permanent, structured, income-generating ecosystems that stimulate local economic growth and create sustainable livelihoods.

Each cluster operates as a growth pole, catalysing development across surrounding villages. This includes the establishment of:

- Community seedling nurseries

- Cluster-owned processing hubs

- Storage and aggregation centres

- Rural entrepreneurship facilities

- Training and demonstration farms

- Local logistics and distribution networks

- Market linkages with urban centres and export gateways

This transformation elevates rural areas from low-income zones into industrial farming corridors, where farmers participate not only in production but also in manufacturing, packaging, trade, and export. These activities generate a ripple effect that stimulates local commerce—shops, transport services, input supply businesses, repair centres, youth cooperatives, and women-led micro-enterprises all emerge around the cluster economy.

The cluster becomes a regional agricultural hub, providing jobs, attracting investment, improving food security, and building rural resilience against climate change and economic shocks. With each additional cluster established, rural Botswana moves closer to achieving balanced national development, reduced inequality, and widespread economic empowerment.

9. Expanded Skills Transfer (Impactation)

A foundational pillar of the Moringa ABC model is skills transfer, which is not limited to simple training but built on the principle of Impactation — the deep-rooted transformation of mindsets, skills, and capacities that elevate individuals from subsistence-level actors into empowered, future-ready agricultural professionals.

Through structured training delivered by Uphopia Farms, Farmer’s Pride International, and the Agriculture-Based Cluster governance system, farmers evolve into:

1. Climate-Smart Producers

Farmers are trained to adopt resilient farming methods that respond to changing weather patterns, conserve water, rehabilitate soil, and maximize productivity using regenerative practices such as mulching, composting, organic pest control, and efficient irrigation systems. This prepares rural farmers to thrive in an era of climate uncertainty.

2. Manufacturers

The cluster model transforms rural farmers into active participants in agro-processing. Members learn how to produce powder, tea, capsules, animal feed, bio-fertilizers, snacks, cereals, cosmetics, and herbal medicines. This transition empowers farmers to benefit from value addition, not just raw production.

3. Exporters

Through training in quality standards, EcoCert, HACCP compliance, traceability, packaging, and international buyer requirements, farmers gain the knowledge and competence necessary to supply regional and global markets. This shifts rural communities from being consumers to international trade contributors.

4. Entrepreneurs

Impactation builds a culture of innovation, business thinking, and enterprise development. Farmers learn:

- Business planning

- Financial management

- Cooperative governance

- Marketing and sales

- Value

chain enterprise development

This transforms farming from a survival activity into a formal, profitable, entrepreneurial venture.

5. Digital-Ready Agricultural Actors

Farmers are empowered with digital tools—mobile apps, farm

management software, GPS mapping, digital record keeping, climate advisory

systems, and online marketplaces.

This prepares rural communities for the future of agriculture, ensuring that

even remote villages participate in digital economies and smart agriculture

technologies.

Rural Transformation Will happen Through Empowered Farmers

Through Rural Development and Impactation, the Moringa ABC model turns rural villages into industrial agro-centres, and farmers into skilled, global-ready economic actors. The result is an inclusive agricultural economy where rural Botswana becomes a generator of wealth, innovation, climate resilience, and national economic growth.

Formation of a Moringa Agriculture-Based Cluster (ABC)

The formation of a Moringa Agriculture-Based Cluster is a structured, compliance-driven, and highly coordinated process designed to ensure that only committed, trained, and technically aligned farmers enter the national Moringa production ecosystem. This approach protects product quality, strengthens market confidence, and guarantees that every cluster meets the standards required for local processing, international certification, and premium export markets.

A cluster is formally constituted when 6, 10, or 20 farmers—all located within a 50-kilometre radius—meet the full set of FPI compliance requirements and demonstrate readiness for collective production, processing, and market participation. The proximity requirement ensures efficiency in logistics, shared resources, monitoring, and centralised processing, while strengthening community cohesion and rural economic integration.

Cluster formation is not accidental; it is a deliberate process built on strong governance, shared accountability, and strict adherence to the national Moringa production protocols under the Rural and Urban Agriculture Innovative Production Programme (RUAIPP).

Eligibility and Compliance Requirements

To participate in this national programme and qualify for cluster formation, every farmer must meet all seven mandatory steps outlined by Farmer’s Pride International (FPI) and Hunter’s Global Network (HGN). These steps ensure that farmers are fully trained, properly registered, technically capable, and aligned with international certification standards.

1. Attendance of Official Moringa Training

Farmers must first complete accredited training delivered by

FPI, Uphopia Farms, and RUAIPP technical teams.

The training equips farmers with:

- Climate-smart farming methods

- High-density production guidelines

- Pest and disease control

- Harvesting and post-harvest handling

- Traceability, compliance, and quality assurance

This ensures that every farmer enters the cluster with the same technical foundation.

2. Registration for HGN / FPI Membership

Registration formalises the farmer’s relationship with the

national programme.

Membership provides:

- Access to agronomic support

- Eligibility for cluster integration

- Inclusion in national farmer databases

- Pathways to grants, inputs, and markets

- Direct linkage to processing hubs and buyer networks

3. Land Assessment Completed and Approved

Before joining the cluster, each farmer undergoes a land

assessment conducted by FPI field officers.

The assessment verifies:

- Soil suitability

- Water availability

- Field accessibility

- Environmental sustainability

- Compliance with EcoCert production standards

This ensures that every farm within the cluster has the capacity to produce at scale.

4. Purchase of 21 Packets of Moringa Seeds

Each farmer must have secured their planting materials—21

packets, which is the minimum threshold for establishing commercial-scale

production under the ABC model.

This requirement confirms:

- Serious commitment

- Readiness to plant

- Ability to contribute meaningfully to cluster supply volumes

5. Start of Moringa Farming Activities

Farmers must have begun land preparation, planting, or

seedling nursery establishment.

This guarantees that cluster formation is built on practical progress, not

theoretical intention.

It also signals that farmers are ready for scaling under cluster coordination.

6. Signing of the Offtaker Agreement with FPI

The Offtaker Agreement is the legal and commercial backbone

of the cluster.

It ensures that farmers:

- Have guaranteed market access

- Are protected from middlemen

- Are assured of stable pricing

- Commit to quality and compliance standards

- Supply output to FPI for processing and export

This agreement strengthens economic security for all cluster members.

7. Application for the Moringa Export Permit (FPI)

Since Moringa is an export-sensitive commodity, farmers must

apply for an export permit through FPI.

This step ensures alignment with:

- National agricultural regulations

- EcoCert and HACCP standards

- Traceability and food safety protocols

- International market requirements

Farmers who complete this step are eligible for export-directed production programs.

The Power of Structured Cluster Formation

Through strict compliance, shared governance, and

proximity-based organisation, the cluster model transforms scattered rural

farmers into a powerful, coordinated agro-industrial force.

By bringing together 6 to 20 farmers within a 50 km radius—each fully trained,

registered, certified, and market-ready—the Moringa ABC framework builds strong,

resilient, and economically vibrant rural economies capable of driving

national transformation.

ABCs EXPLANATION TO FARMERS:

HOW HUNTER’S GLOBAL NETWORK (HGN) WILL FUND AND SUPPORT EACH MORINGA AGRICULTURE-BASED CLUSTER (ABCs)

(Project Duration: 3–5 Years / Equity-Based Partnership Model)

1. Introduction

Kindly share the following message with your Cluter members:

Therough the BETP Investments, Hunter’s Global Network (HGN) is establishing a structured, transparent, and fair investment model to fund all Moringa Agriculture-Based Clusters (ABCs) across Botswana. Under this model, HGN partners with farmers through an equity arrangement, ensuring long-term sustainability, accountability, and shared prosperity.

This model is designed to build strong clusters, guarantee full compliance, and position every farmer for export markets, high-value processing, carbon earnings, and long-term generational wealth.

2. HOW FUNDING WORKS: 50% EQUITY, 50% FARMER OWNERSHIP

Each cluster will be formally registered with CIPA as a

Company (Pty Ltd).

Ownership will be structured as follows:

- 50% Shares – Hunter’s Global Network (HGN)

- 50% Shares – Cluster Farmers (shared proportionally as per cluster constitution)

Why Equity?

Because HGN is not giving grants. It is investing heavily in:

- Land development

- Irrigation

- Infrastructure

- Seeds and seedlings

- Labour

- Training

- Machinery

- Compliance and certification

- Market access and exports

- Management and technical experts

- Cluster governance and reporting

This equity model ensures all parties are responsible, committed, and compliant.

3. WHAT HGN WILL FUND (FULL COST COVERAGE)

For the entire 3–5-year agreement period, HGN will finance 100% of cluster establishment and operations, including:

A. Pre-Production Phase

- Land identification and purchase

- Land surveying and assessment

- Environmental and water assessments

- Full land preparation (clearing, ripping, ploughing)

- Borehole drilling or water sourcing

- Installation of water tanks and reservoirs

- Cluster legal registration and compliance through CIPA

- EcoCert and SPS compliance setup

- Baseline mapping of farms

- Cluster governance formation

B. Production Phase

- Procurement of seeds and seedlings

- Installation of irrigation systems (pipes, pumps, filters, valves)

- Drip irrigation or overhead systems

- Nursery setup for 70,000 trees per hectare model

- Farm inputs (fertilizers, organic boosters, chemicals)

- Labour for planting, weeding, pruning, harvesting

- Machinery (tractors, implements, sprayers)

- Pest and disease management systems

- Crop insurance and risk management

- Soil health management

C. Post-Harvest & Processing Phase

- Construction of drying sheds

- Construction of storage facilities

- Solar drying equipment

- Processing machines (mills, grinders, oil presses, capsule machines)

- Packaging materials

- Quality control tools (moisture meters, HPLC testing support)

- Full traceability systems (QR codes, batch numbers)

- Export packaging and labeling

- Market certification and international approvals

D. Operational & Management Support

- Hiring full-time farm managers

- Cluster accountant and bookkeeper

- HR and payroll support

- Compliance officers

- Technical advisors and agronomists

- Training sessions (ongoing)

- Field team-building workshops

- Governance, leadership and board meetings

- Climate-smart monitoring, satellite mapping, and productivity tracking

4. WHAT REMAINS CLUSTER PROPERTY

All assets developed during the life of the project automatically become property of the cluster at the end of the agreement:

- Land

- Boreholes and water infrastructure

- Buildings

- Drying sheds

- Storage facilities

- Processing equipment

- Machinery and tools

- Irrigation systems

- Nursery structures

- Solar systems

- All improvements on the farm

Farmers will inherit a fully developed, export-ready commercial farm.

5. ROLE OF HGN DURING THE 3–5 YEAR PARTNERSHIP

HGN will bring:

- Capital investment

- Technical expertise

- Compliance systems

- Access to export buyers

- Management personnel

- Training programs

- Full mechanization

- Insurance coverage

- Guaranteed off-take

- Governance and audits

- Access to carbon markets

This ensures that clusters operate at industrial, export, and global standards.

6. EXIT STRATEGY: BUYING BACK HGN SHARES

After 3–5 years, when the cluster is strong, profitable, and fully established:

- HGN will exit the partnership.

- The cluster will buy back HGN’s 50% shares.

- Ownership will then become 100% farmer-owned.

The share buy-back process will be:

- Transparent

- Valuation-based

- Audited

- Guided by the cluster constitution

- Payable through revenue, profits, or structured settlement

This ensures farmers completely own all infrastructure, machinery, buildings, and the full business.

7. SUMMARY FOR FARMERS

To be funded by HGN, a cluster must be:

- Registered under CIPA

- Compliant with FPI/HGN requirements

- Governed professionally

- Participating in the national ABC system

Once approved, HGN will:

- Fund the entire project

- Manage the cluster

- Build full infrastructure

- Provide machinery and processing equipment

- Secure export markets

- Support for 3–5 years

- Exit by allowing farmers to buy back its shares

This model ensures:

- Generational wealth

- Rural industrialisation

- Guaranteed markets

- Long-term sustainability

- Nation-wide job creation

- Increased GDP contribution for Botswan

8. Conclusion

Moringa Oleifera Agriculture-Based Clusters are Botswana’s bridge to agricultural industrialization—a blueprint that links production, processing, markets, empowerment, and climate resilience into one unified national programme.

They are an engine for value addition, job creation, youth empowerment, and GDP growth. By building ABCs across all districts, Botswana positions itself as Africa’s leading producer and exporter of Moringa, creating generational wealth and transforming rural communities into productive, sustainable economic hubs.

For more information contact:

Hunter – Executive President

Hunter’s Global Network PTY LTD & Farmer’s Pride International

Plot: 1157, Mmopane Block 1, Gaborone, Botswana

E-mails:

Farmer’s Pride Linktree:

https://linktr.ee/farmerspride.int

.png)

.png)

.png)

.png)

.png)

Comments

Post a Comment